1. TECHNICAL STANDARDS

Article 1. This standard stipulates the stages of packing, storing and transporting rubber products in factories to ensure quality and bring high economic efficiency.

Article 2. Regulations are presented in the form of technical legal documents, issued by the Board of Directors of Vietnam Rubber Group – Joint Stock Company.

Article 3. This regulation must satisfy the following requirements:

3.1. Meet the quality of rubber products according to ISO, TCVN, TCCS and/or customer requirements.

3.2. Advanced in science and technology.

3.3. The rubber factories of Vietnam Rubber Industry Group – Joint Stock Company can be applied.

3.4. High economic efficiency.

3.5. Does not adversely affect health, occupational safety, national security and the environment.

2. REGULATIONS ON PACKAGING, STORAGE OF FINISHED RUBBER PRODUCTS AND RUBBER SHEET

Article 4. Backaging:

4.1. The rubber bale is wrapped with LDPE (low density polyethylene) plastic bag, the melting temperature is not more than 109 0C, the dimensions are as follows:

- Length: ≥ 1 000 mm.

- Horizontal : ≥ 580 mm.

- Thickness: 0.03 mm 0.05 mm

PE bag type and thickness can be changed according to customer requirements.

4.2. The mark on the rubber bale must match with the type and grade of rubber.

4.3. After wrapping, the plastic bag must be sealed and not torn.

4.4. With 111,111 kg RSS rubber: after pressing, the bale is wrapped with pre-selected sheets of rubber from within the bag, talc-brushed and painted in a clean, separate area.

Article 5. Rubber containers

5.1. The rubber bale is packed in pallets

5.1.1. The rubber balls are placed in a container lined with 02 opaque white or colorless PE plastic mats, covering all six sides of the container, from 0.07 mm to 0.10 mm thick. Container specifications are based on:

– TCCS 115 – finished rubber containers in commercial transactions of Vietnam Rubber Group – Joint Stock Company.

– Containers agreed upon by the customer and the goods owner.

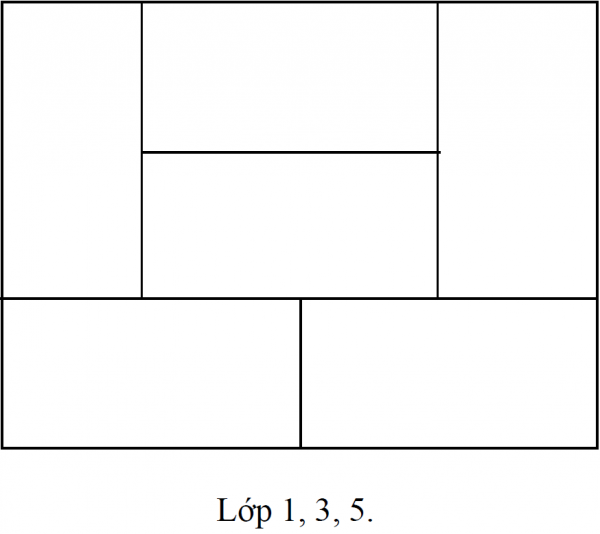

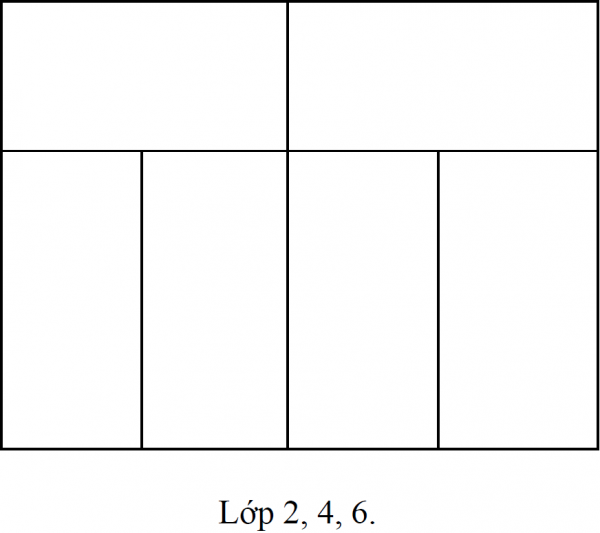

5.1.2. Arrange the rubber bale in 6 layers according to the following regulations:

Or according to customer’s request.

5.1.3. Each layer of rubber is placed with an additional PE sheet separating the two layers; or spread in a zigzag pattern starting from the bottom layer to the top layer of the rubber layers in the container and have a thickness of 0.07 mm to 0.10 mm; or according to customer’s request.

5.1.4. Put the lid on the container when filled with rubber, move the container to the specified place in the warehouse. Use the weight of another container filled with rubber placed on top to compress the rubber to fit in the container. Do not stack more than 3 rubber buckets on top of each other.

5.1.5. During bracing, it is necessary to check and handle the phenomenon of deformed pus spilling outside the mouth of the container (if any).

5.1.6. The time of rubber compression must ensure that the rubber is stable in shape, the lid of the barrel is covered with the rubber container.

5.2. For finished products, heat shrinkable PE packaging (shinkwrap) is used.

5.2.1. Wooden pallet base, metal or plastic depending on customer requirements.

5.2.2. Rubber is shaped in iron or wooden crates. The rubber balls are placed in a container lined with 02 opaque white or colorless PE plastic mats, covering all six sides of the container, from 0.07 mm to 0.10 mm thick.

5.2.3. Arrange the rubber balls one by one into 6 layers according to the regulations as in Section 5.1.2.

5.2.4. Each rubber layer is placed an additional PE sheet separating the 2 layers; or spread in a zigzag pattern starting from the bottom layer to the top layer of the rubber layers in the container and have a thickness of 0.07 mm to 0.10 mm; or according to customer’s request.

5.2.5. Put the lid on the container when filled with rubber, move the container to the specified place in the warehouse. Use the weight of another container filled with rubber placed on top to compress the rubber to fit in the container. Do not stack more than 4 boxes on top of each other for iron crates and 3 boxes for wooden crates.

5.2.6. The time of rubber compression must ensure that the rubber is stable in shape, the lid of the barrel is covered with the rubber container.

5.3. For rubber RSS ball 111,111 kg:

5.3.1. Four rubber balls are placed on a wooden base – tole.

5.3.2. Use the weight of another piece of wood filled with rubber placed on top to brace the rubber ball, ensuring that the rubber ball is stable in shape.

Article 6. Packaging finishing and packaging labeling

6.1. For finished rubber products in pallets: Open the lid from the container, cover 2 PE mats to cover the bales, close the lid. Complete the product and mark the product.

6.2. For finished products using heat shrinkable PE packaging: remove the containers, cover 2 PE mats to cover the bags, paste product information boards directly on 02 long sides of latex bales, cover with shrink PE bags. heat; Finish the packaging and shape the rubber on the pallet base with straps.

6.3. Product symbols are recorded according to:

- TCCS 115 – finished rubber containers in commercial transactions of Vietnam Rubber Industry Group – Joint Stock Company.

- According to the sale and purchase contract.

6.4. In case the expected grade of rubber is not consistent with the test results, the consignment shall be adjusted according to the procedures for non-conforming products; clarify the cause, take corrective and preventive measures.

Article 7. Warehouse conditions.

7.1. Storage warehouses must be clean, well-ventilated, not wet, covered from sun and rain.

7.2. The warehouse floor must be flat and high enough to prevent water from overflowing from the outside. The storage floor ensures that it is not permeable, has enough strength to withstand the load of stored finished products and transport vehicles.

7.3. The temperature in the warehouse should not exceed 40 0C.

7.4. The warehouse must be equipped with fire prevention and fighting equipment in accordance with state regulations.

7.5. The door of the warehouse in the loading area must have a rain cover and be wide enough to load the goods onto the transport vehicle.

Article 8. Storage

8.1. For finished products contained in pallets.

8.1.1. Stacking rubber containers in batches and rows; goods are separated from the other, at least 0.5 meters from the warehouse wall and according to the regulations of fire prevention and fighting.

8.1.2. Arranged according to the warehouse diagram, the batch that is produced first will be shipped first (FiFo – First in First out principle).

8.1.3. Rubber containers in the warehouse must not be stacked more than 03 boxes on top of each other.

8.2. For rubber in bulk storage.

8.2.1. Detachable rubber is placed on the pallet base or on an anti-re-contamination and moisture-proof pad. Check and replace damaged packaging.

8.2.2. The rubber in the warehouse must not be stacked more than 06 layers, put the rubber balls in turn according to the provisions in Section 5.1.2 and in batches.

8.2.3. Divide the warehouse into small areas, each area contains about 20 tons of rubber (depending on the conditions of the warehouse), each area is 0.5 meters apart and according to the regulations of fire protection (can be retrofitted).

8.2.4. Arrange according to the warehouse diagram, export according to the FiFo principle.

8.3. For finished products, heat shrinkable PE packaging (shinkwrap) is used.

8.3.1. Stacking rubber profiles in batches and rows; goods are separated from the other, at least 0.5 meters from the warehouse wall and according to the regulations of fire prevention and fighting.

8.3.2. Arrange according to the warehouse diagram, export according to the FiFo principle.

8.3.3. Iron rubber containers in the warehouse must not be stacked more than 04 rubber barrels and 03 boxes for wooden crates.

8.4. For rubber ball RSS 111,111 kg

8.4.1. Arrange the rubber mazes in batches and rows; goods are separated from the other, at least 0.5 meters from the warehouse wall and according to the regulations of fire prevention and fighting.

8.4.2. Arrange according to the warehouse diagram, export according to the FiFo principle.

8.4.3. Wood maze – rubber tole in storage must not be stacked more than 04 layers.

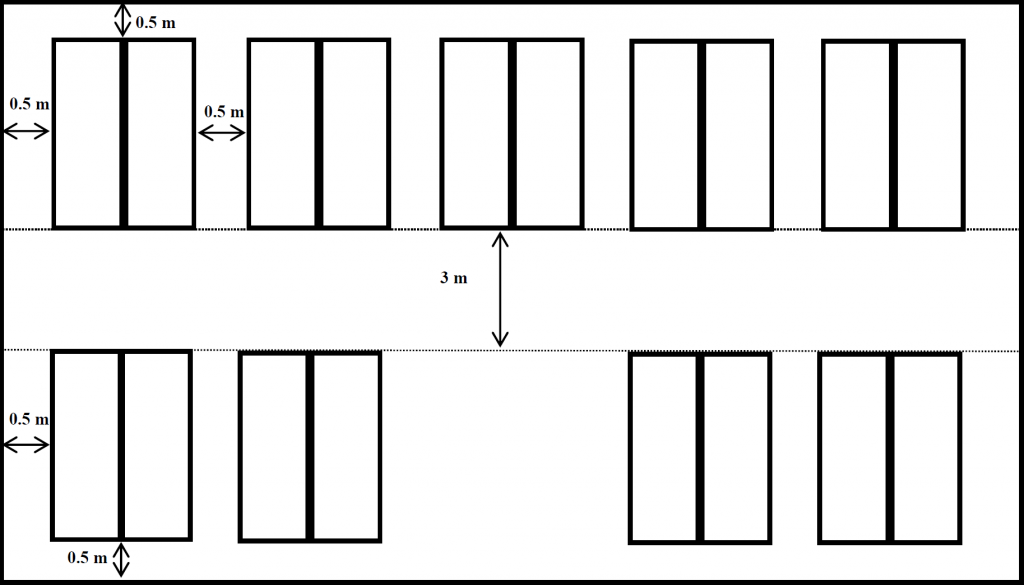

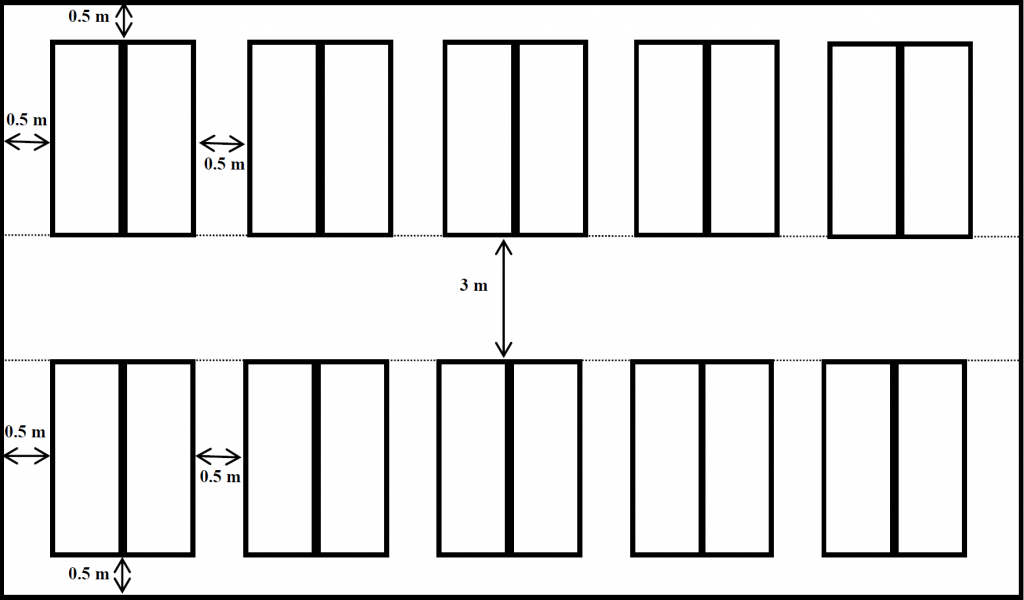

8.5. Warehouse arrangement model:

8.5.1. Warehouses leave aisles wide enough for vehicles to move in the warehouse at least 3 meters.

8.5.2. In case the warehouse door is located at the two ends of the warehouse.

8.5.3 In case the warehouse door is located on the side of the warehouse.