EXPORT PACKING PROCESS

I. PACKING PUMP AND LAST FLAG RSS:

1. Packing bulk goods into Container:

+ For the weight of 33.33 kgs:

• Packing 576 bales per 20′ container (corresponding to 19.2 tons).

• Packing 600 bales per 20′ container (corresponding to 20.16 tons).

• Packing 630 bales per 20′ container (equivalent to 21 tons).

+ For the type of ball weight 35 kgs:

• Packing 576 bales per 20′ container (corresponding to 20.16 tons).

• Packing 600 bales per 20′ container (equivalent to 21 tons).

+ For the RSS sheet with the weight of 111 kgs:

• Packing 180 bags per 20′ container (equivalent to 20.00 tons)

2. Close Pallet Shrink wrapped with plastic base:

Each pallet stacks 36 bags in 6 layers on a plastic base and is tightly wrapped with thick, opaque PE bags. Each pallet is securely strapped. Packing method:

+ For the weight of 33.33 kgs:

Net weight: 1,200 kgs/pallet, Gross weight: 1,240 kgs/pallet, 16 pallets packed into a 20′ container.

+ For the type of ball weight 35 kgs:

Net weight: 1,260 kgs/pallet, Gross weight: 1,300 kgs/pallet, 16 pallets packed into a 20′ container.

3. Close pallet shrink wrapped wooden base:

Each pallet is arranged in 36 layers in 6 layers on a wooden base, the wood material is guaranteed to be free of termites and is tightly packed with thick, opaque PE bags. Each pallet is secured with 4 straps.

Packing method:

+ For the weight of 33.33 kgs: a

Net weight: 1,200 kgs/pallet, Gross weight: 1,240 kgs/pallaaoaoaoet, 16 pallets packed into a 20′ container.

+ For the type of ball weight 35 kgs:

Net weight: 1,260 kgs/pallet, Gross weight: 1,300 kgs/pallet, 16 pallets packed into a 20′ container.

4. Packing wooden pallets:

Each pallet is arranged in 36 layers into 6 layers, the wood material is guaranteed to be free of termites and termites, with dimensions of 1425 mm x 1100 mm x 1067 mm. Two thick, opaque PE sheets are lined in the pallet and covered on six sides of the pallet. Each pallet is strapped with an iron belt.

Packing method:

+ For the weight of 33.33 kgs:

Net weight: 1,200 kgs/pallet, gross weight: 1,300 kgs/pallet, 16 pallets packed into a 20′ container.

+ For the type of ball weight 35 kgs:

Net weight: 1,260 kgs/pallet, Gross weight: 1,360 kgs/pallet, 16 pallets packed into a 20′ container.

5. Close the iron pallet

Each pallet stacks 36 pieces in 6 layers with dimensions of 1425 mm x 1100 mm x 1067 mm. Two thick, opaque PE sheets are lined in the pallet and covered on six sides of the pallet.

Packing method:

+ For the weight of 33.33 kgs:

Net weight: 1,200 kgs/pallet, gross weight: 1,300 kgs/pallet, 16 pallets packed into a 20′ container.

+ For the type of ball weight 35 kgs:

Net weight: 1,260 kgs/pallet, Gross weight: 1,360 kgs/pallet, 16 pallets packed into a 20′ container.

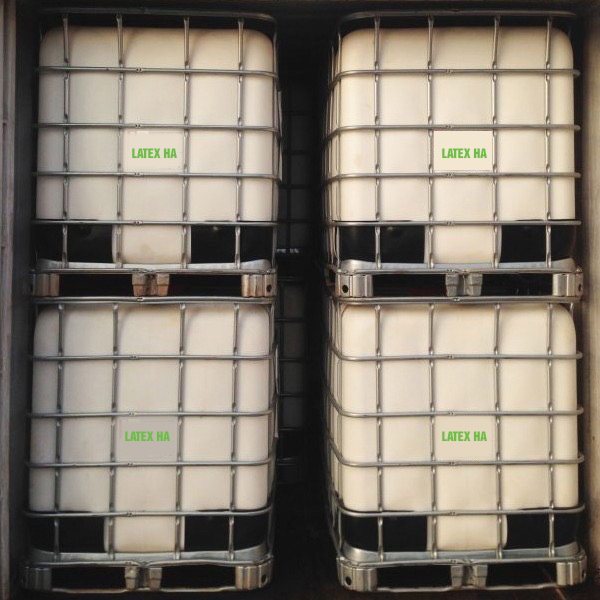

II. PACKING LATEX RUBBER:

There are two options:

+ Flexi-Bag: Packed in bulk with a Flexibag (Flexitank) that is firmly positioned into the container, Flexibag is a specialized bag for packing liquid products, the bag material can be rubber. , plastic or synthetic fiber. The bag has valve design for closing and discharging Latex rubber, with low cost nowadays Flexibag bags are widely used. Each Flexibag can hold 21 tons of HA or LA 60% latex in a 20f container.

+ IBC tank: is a type of blanket contained in pallets with iron frame, wall is made of hard carton, 1 ton/barrel, 20 cartons/container 20f.

+ Iron drum: Weighs 205kg (55 gallons)/phi. This is a popular packaging method in the rubber industry, the outside is painted blue or black depending on the customer’s requirements, the inside is coated with Bitumen or Epoxy. Each 20f container can hold 80 drums, equivalent to 16.4 tons.

• DELIVERY METHOD:

– For domestic customers: Delivered at the seller’s processing factory, delivered at a designated place designated by the buyer.

– For foreign customers: FOB, CFR, CIF…. or other methods as agreed in the Contract, which are complied with International Commercial Law.